Authors: A. Salimian, E. Foroozmehr, M. Badrossamay

Address: Journal of Modares Mechanical Engineering, Vol.15,Issue 7, pp 73-79

Abstract

Authors: A. Salimian, E. Foroozmehr, M. Badrossamay

Address: Journal of Modares Mechanical Engineering, Vol.15,Issue 7, pp 73-79

Abstract

Authors: A.Salimianrizi, E.Foroozmehr, M.Badrossamay, H.Farrokhpour

Address: Journal of Optics and Lasers in Engineering, Volume 77, February 2016, Pages 112–117

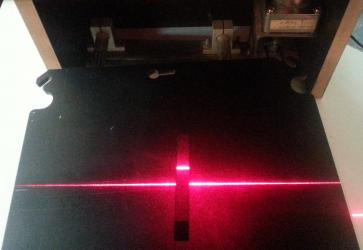

Laser shock peening (LSP) is a surface treatment process that is performed to improve the fatigue life of components. In this process by applying a pulse of laser energy and shock wave propagation in the component, a compressive residual stress field in the metal piece is created (Figure below). The main task of LSP is creating compressive residual stress and strain due to surface hardening that can improve the mechanical properties such as resistance to fatigue and corrosion of the metal parts.

|

| Laser Scanner |

A 3D scanner is a device that analyses a real-world object or environment to collect data on its shape and possibly its appearance (e.g. colour). The collected data can then be used to construct digital three-dimensional models.

The Laser Photodisruptor is one of the key ophthalmological devices which today has become a necessary medical laser tool for ophthalmology clinics. Using this device, two common eye surgery, capsulotomy and iridotomy and more recently laser vitreolysis are performed as a non-invasive treatment of secondary cataract, angle closure glaucoma and floaters respectively. As the laser-tissue interaction mechanism which caused by said device is photodisruption, it is called laser phodisruptor.

Authors: Behnam Goodarzy, Ehsan Foroozmehr and Hamidreza Alemohammad

Address: Journal of Smart Materials and Structures, Volume 25, Number 2

Laser cladding process includes transferring a desired material to a substrate and melting it by a laser heat source. The purpose of this process is depositing a thin layer of a desired metal on a substrate. Different geometries of deposition can be obtained by moving substrate in 2D plane. There are several methods for transferring the deposited material to the substrate: powder injection, pre-placed powder on the substrate and wire feeding.

Laser engraving and marking is one of the laser material processing sections in which the laser power is used to mark or engrave a surface. A focused laser beam is targeted on a surface and by evaporating the material (engraving) or changing the material texture (marking) affects the material. Laser engraving has many applications in different industries. In LO Lab, a project on laser engraving of gas pipelines was defined by Isfahan Gas Company.

|

| Laser Cutting by CW CO2 Laser |

Laser Cutting was the first application of laser after its invention. Since then, many researches have been performed on advancement of this technology. in LO Lab, the following projects have been completed so far: