Laser engraving and marking is one of the laser material processing sections in which the laser power is used to mark or engrave a surface. A focused laser beam is targeted on a surface and by evaporating the material (engraving) or changing the material texture (marking) affects the material. Laser engraving has many applications in different industries. In LO Lab, a project on laser engraving of gas pipelines was defined by Isfahan Gas Company. The focus of this project was to determine processing window so that laser engraving gas pipe lines does not violate the API and IGS standards. If that can happen, this method would be added to the standards so that any pipe manufactured by a company can be traced for over two years in werehouses or after burying the pipes.

|

| Gas pipes needed to be marked for tracing purposes |

A pulsed Nd:YAG system was used to study the process. An intensive study on the effects of main process parameters on the depth and shape of the engraved surfaces was performed. In addition, the effect of aplying such defect on the material on the strength and corrosion resistance of the material were studied. Some of the results are shown below.

|

|

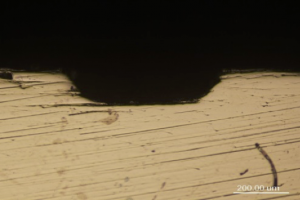

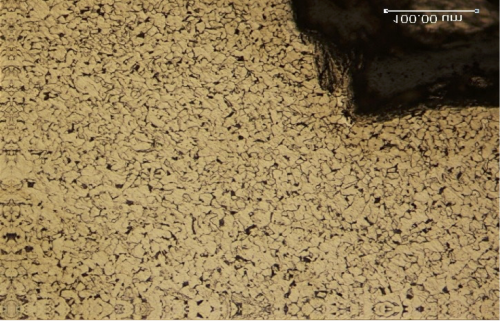

| Cross section of a sample with initial process parameters | Cross section of a sample with optimized process parameters |

|

| No noticeable HAZ considering the optimized parameters |

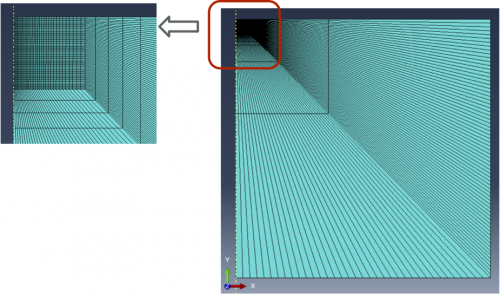

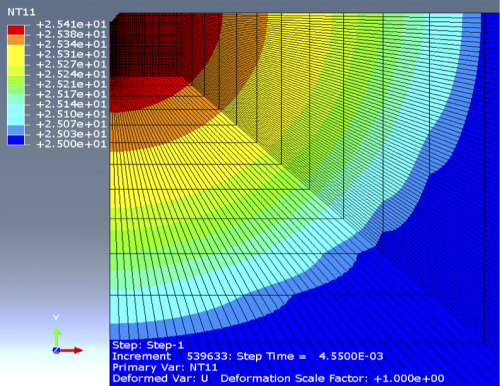

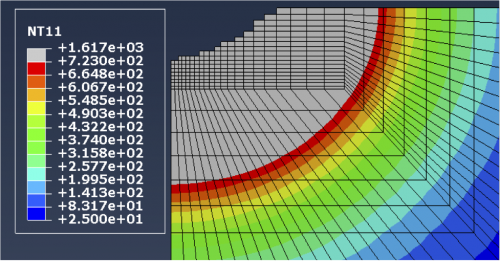

The optimized process parameters were obtained based on the minimum processing time and minimal heating effect on the material. The absence of any HAZ in the cross section view implies that the pulsed nature of the process prevents heat accumulation in the material. In order to confirm such observation, a finite element simulation was performed. The pulsed laser power was applied to the surface and overheated material was removed in a step-wise process. The results are shown below:

|

| Meshed structure of the simulation |

|

| Temperature distribution right before the second pulse hits the surface. It confirms the fact that temperature reaches room temperature after each pulse |

|

| The grey region shows the HAZ. The depth is about 20 micrometer. |

The FEM results show that no heat accumulation occurs with the considered process parameters. In addition, the HAZ is very small and can be considered to be no harmful to the material.

This research in ongoing and corrosion resistance experiments and speeding up the engraving process is under investigation. The researchers of this project are Saeed Taghiyar and Behnam Khashei.