|

| Laser Cutting by CW CO2 Laser |

Laser Cutting was the first application of laser after its invention. Since then, many researches have been performed on advancement of this technology. in LO Lab, the following projects have been completed so far:

- Laser cutting of Titanium sheet

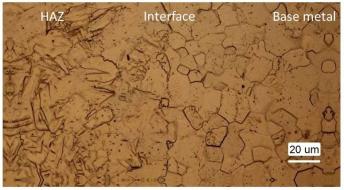

In this research, CO2 laser system was used to cut think sheet of Ti-CP. The main goal of this research was to study the main parameters affecting the HAZ. Microstructure analysis and micro-hardness test were used in this study. The following figures show the cutting kerf and microstructre of the HAZ.

|

|

| Cutting line created by one of the experiences | The difference between HAZ and BM in one of the experiences |

The results indicate that the cutting speed has a significant effect on HAZ. Assistant gas type has less noticeable effect on the area affected by the heat. The effects of the system power and Stand-off distance are negligible. Contour area chart is presented in Fig. 5 to investigate the effect of speed and type of assistant gas parameters that has the highest influence on the HAZ width.

This study has been done by Mohamad Sadegh Amjadi.

- Laser Cutting of Steel Sheet

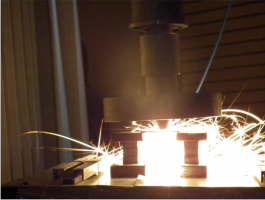

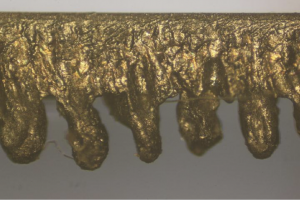

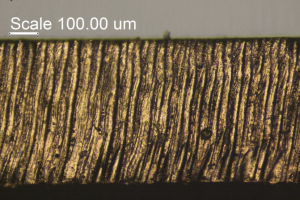

In this research, a low power CO2 Laser was used for cutting of low carbon steel sheet. In this research a laser cutting head was designed and fabricated in LO Lab. A series of experiments was performed to find the optimized parameters for cutting the thickest possible steel sheet. The results show that with an actual power of 130W CO2 laser power, 1.5mm Mild Steel sheets were able to be cut. The follwoing figures show the results for this section.

|

|

|

| Laser Cutting Process | Dross formation in Laser cutting of Stainless Steel | Striation formation in laser cutting |

This study has been done by Ashkan Arpanahzadeh.